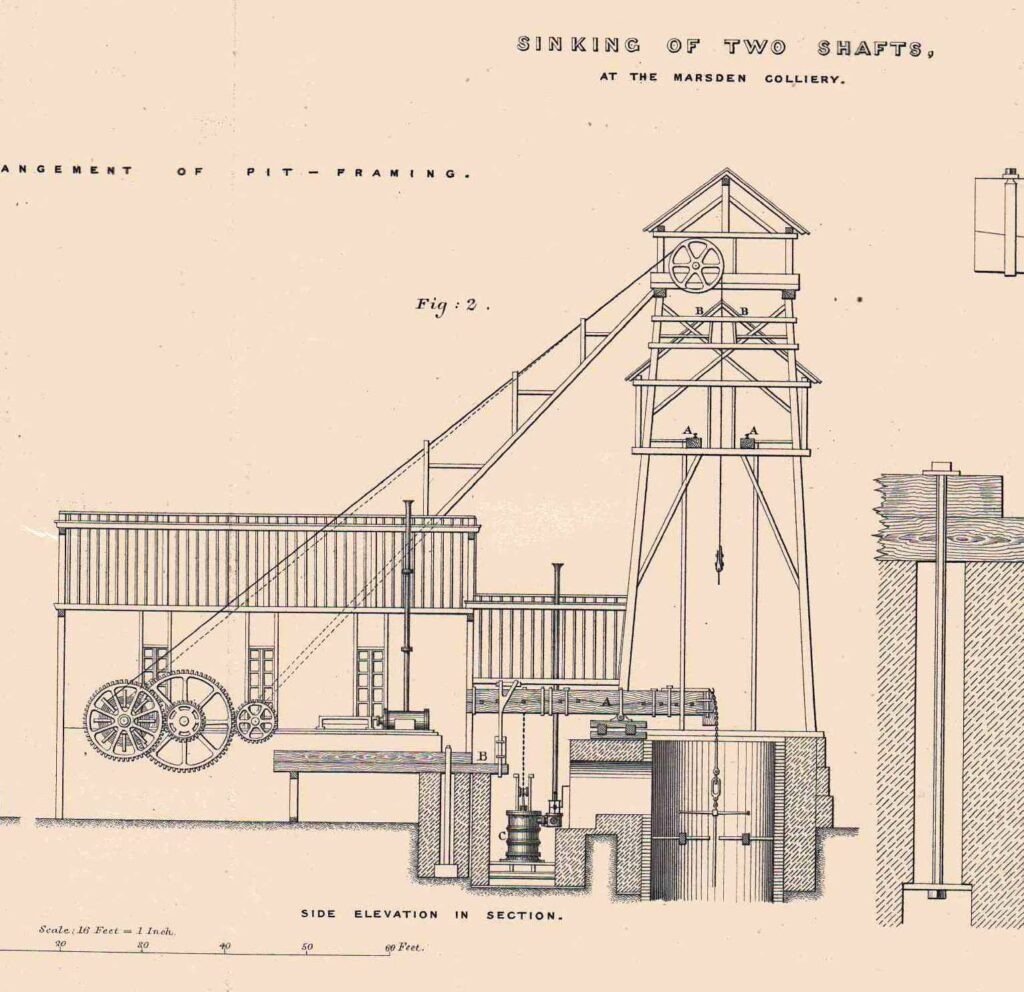

In the mid 1800’s the Whitburn Coal Company obtained the Marsden royalties. To win this area it was decided to sink two shafts 500 yards south of Souter Point Lighthouse and 400 yards from the sea. In 1882 John Daglish who had been the Chief Engineer on the project produced a discussion paper entitled “On the Sinking of two shafts at Marsden, for the Whitburn Coal Company”

Sinking commenced on the 23rd December 1874 and problems occurred immediately with water. At one point more than 12,000 gallons per minute was being pumped from the shaft. It was decided to stop the sinking and rethink the project.

It was decided to restart the sinking using the Kind – Chaudron process.

On the 2nd of May 1877 steps were taken to remove the headgear at No1 shaft (which had been erected and used for ordinary sinking), as it was intended to utilize this shaft, so far as was already sunk, and to continue the sinking of a somewhat smaller pit within the Kind-Chaudron process. The diameter of 14 feet 3 inches was ultimately chosen for this shaft.

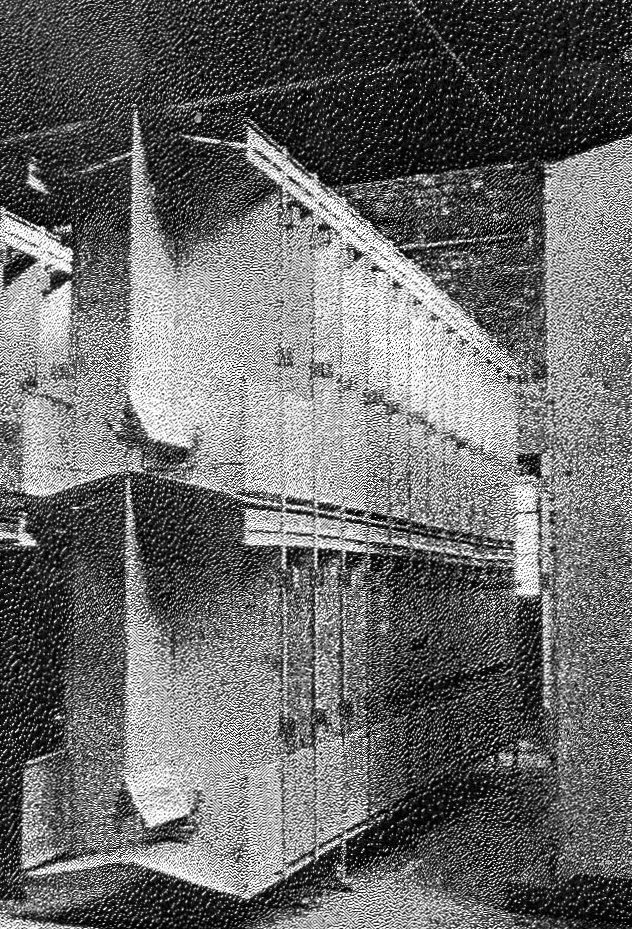

This system of sinking was invented by Messrs. Kind and Chaudron. The system consists of boring out the shaft from the surface, until the watery strata have been pierced, and a suitable foundation obtained on which to place the cast-iron tubbing. The tubbing, composed of rings the full size of the shaft, is then lowered into position, and by means of an ingenious stuffing-box arrangement at the bottom, packed with moss, a water-tight joint is formed as soon as it rests on the bed prepared for it. The water contained in the shaft is then removed, and sinking in the dry measures is then carried on in the usual manner. It was noted during the project to the excellent workmanship and quality of the metal of the Tubbing supplied by the Elswick Ordnance Works.

Belgian engineers were brought over to help with the process. No 1 Shaft was commenced on the 24th September 1877 and was completed on the 4th January 1879. No 2 shaft was commenced on the 20th October 1879 and was complete on 21st May 1881.

Coal production commenced in 1882.

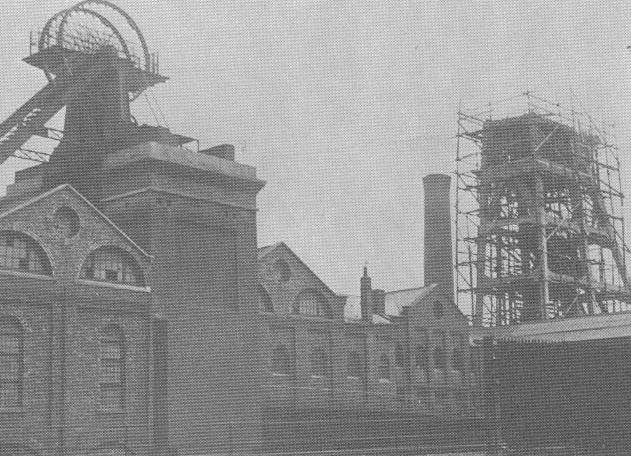

In 1891 the Whitburn Coal Company hit financial difficulties and the colliery was absorbed into the Harton Coal Company.

In 1931 the pit had set a world record producing 18,000 tons of coal per week, with a work force of 1,600.

Vesting Day, January 1, 1947, saw the nationalisation of the British coal industry. Whitburn colliery along with 900 other collieries were now in public ownership under the National Coal Board.

By 1967 rumours were starting to be spread that Whitburn colliery was to be closed as part of a rationalisation plan for the coal industry. In January 1968 the N.C.B. told the men the weekly tonnage of coal that had to be produced to keep the pit open. In May this total had been exceeded and two weeks later the pit was closed. The final shift came up from the shaft bottom on 7th June.

Notable people to worked at Whitburn Colliery

Robert “Bob” Olley — artist and sculptor.

Peter Lee — General Secretary of the Durham Miners’ Association 1930 -1935.

From the biography of Peter Lee written by Jack Lawson MP 1948: (During a spell working in Marsden colliery, Peter had found a friend in a young schoolmaster who sensed Peter’s qualities and taught him to read and write. The teachings and learning’s went on for two years).

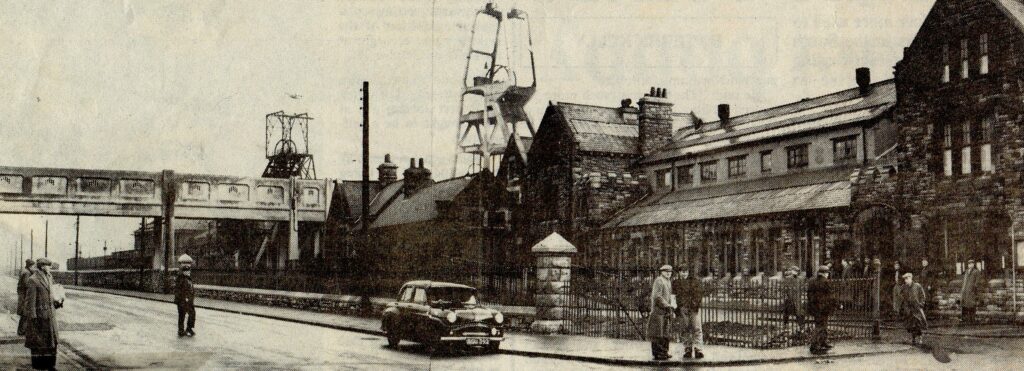

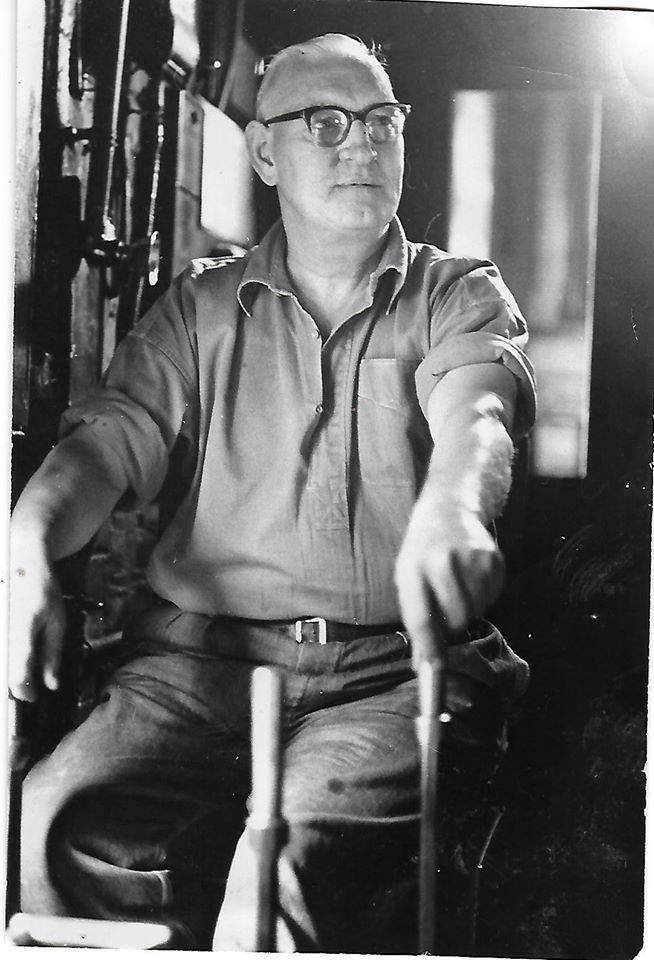

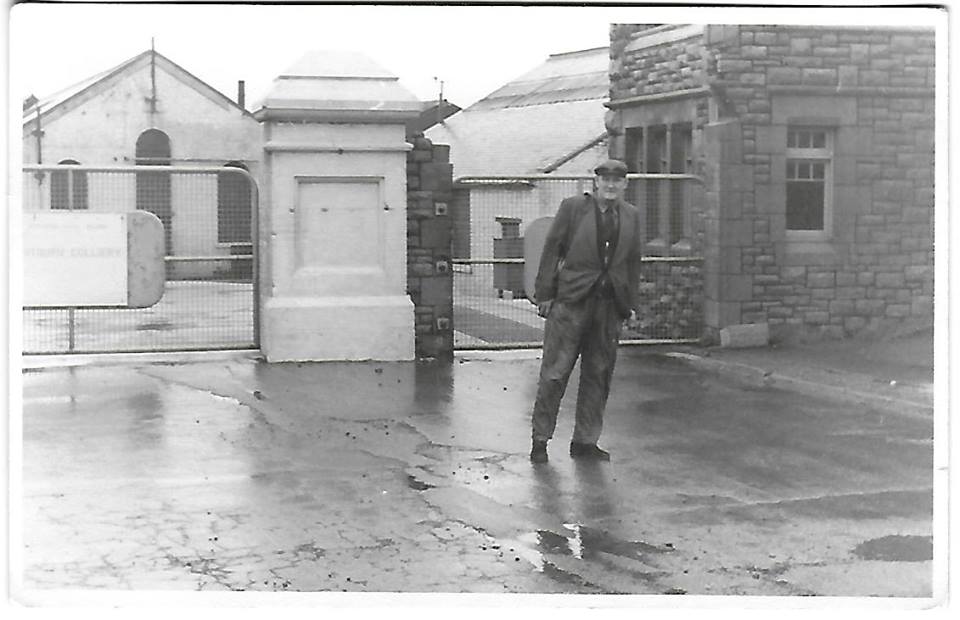

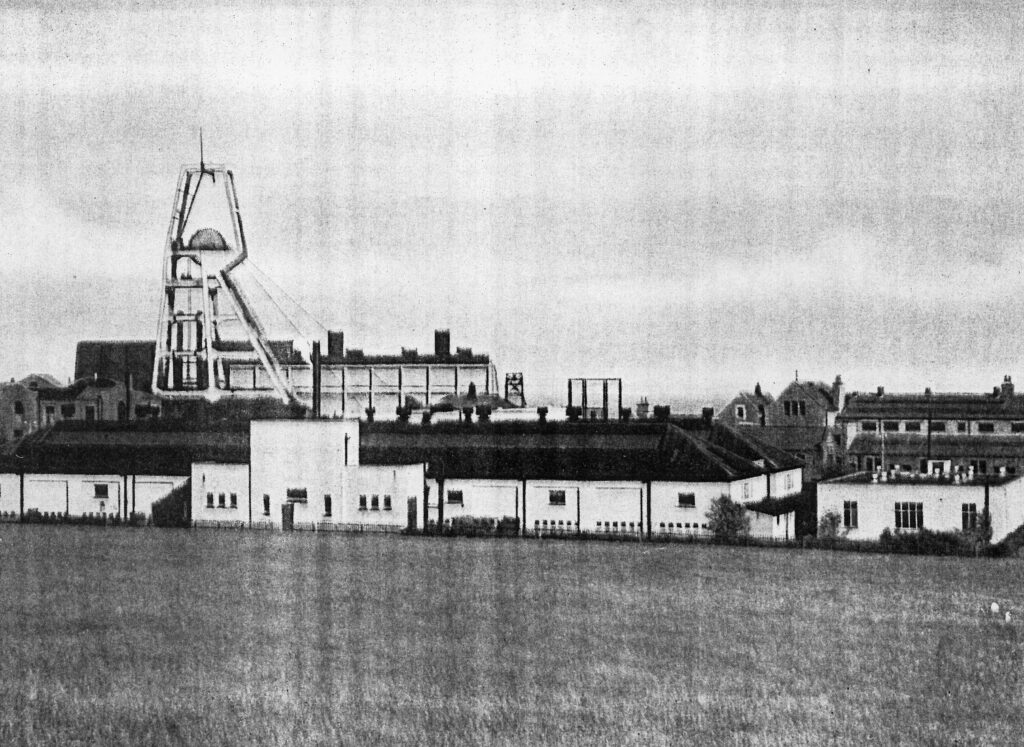

Further Photos of Whitburn

Photographs courtesy of James daughter Eileen Davison

B Cauwood 2013

updated 2020

All copyrights acknowledged were known.

Copyright © 2013 Marsden Banner Group.

All rights reserved. Permission granted to reproduce text for educational use only (please cite source).