These are the memories of Peter Webber who worked at Whitburn from 1961 until the pit was abandoned in 1968.

I started work at 15 years of age at Whitburn in Sept 1961. I travelled daily to Washington for 13 weeks training to allow me to work underground when I became 16 years of age. This training consisted of 7 weeks at Dame Margaret Hall for theory training and 6 weeks at Washington F pit for practical training.

After training was completed I commenced work on the pit heap pushing tubs from cage to tippler and back to cage, after a few months went to work in timber yard assisting Labourers. In June 1962 I won an apprenticeship as a fitter to commence in September 1962, the first 10 months of this was spent full time at Hebburn technical college.

At this time I was a regular at the Marsden Grotto playing darts every night, amongst the players was Bobby Hood, I made friends with Bobby and his wife Joan who was like a second mother to me.

In June 1963 I commenced work in the fitting shop, one of the foremen was Paddy Turner who I also knew from the Grotto, he used to tell me to go with Bobby Hood who was the fitting shop welder to help him haul his Lobster pots. We would be missing for a couple of hours each day hauling the pots, Bobby kept the boat at the Wharry, the first time we launched it down the rollers into the water I was told not to stop pushing till boat was completely in water. Unfortunately that first time my boiler suit pocket caught on the row-lock and the momentum pulled me under the water, I was like a drowned rat to Bobby’s amusement, that was a trick that never happened again.

I also used to go fishing in Jimmy Robson’s boat, Jimmy was also a dart player from the Grotto, he never worked but was very good with his hands, and my 93 year old mother still has a clothes horse he made her for 5 bob. Jimmy had several young sons and lived in the houses across the road from the pit, he had an allotment and hut there which he had tapped into a lamp post to supply electricity. Can remember one day when we were stood up in the boat ripping and pulling up cod every couple of minutes, we must have caught at least 30 to 40 cod, Jimmy gave me 4 large ones to take home. At the time I lived in Quarry Lane Marsden, a twenty minute walk over the high road, I thought I was the bees knees with these fish slung over my shoulder, several motorists stopped and asked if any were for sale, but I said no as I just wanted my neighbours to see them.

When I started working in the fitting shop the other apprentices included, Billy Durrant who had a shop in Whitburn, Billy Prince who went to work for Dosco as a service rep travelling all over the World, unfortunately on a visit to Wearmouth Colliery he was killed in an underground accident in the early 90s. Another Whitburn lad was Bobby Taylor. From Shields there was me, Alan Harvey and Billy Taylor, Billy was nicknamed Donkey for obvious reasons, one week Billy went missing and his father Albert who was a deputy came to the fitting shop to see if any of us knew of his whereabouts. We made enquiries and found out that a couple of stewardesses had smuggled him on board the mailboat to Norway, after he had been missing for 6 weeks Billy Mac the engineer called us to his office and told us to get word to Billy if he did not return to work by the following week he was sacked. He came back the following week a hero in all our eyes.

In the fitting shop we had old Norman who was shop foreman, Bobby Hood who was fitting shop welder, Jim Bailey who operated the large lathe. Norman Carter who sharpened all the cutting picks and drills on his own little grinder at bottom of the shop. There were 3 fitters, Billy Arkly, Herbie Foster and Raymond Robinson who I mostly worked with. Raymond maintained the winding engines along with the shaft bottom pumps, one day he told me to go to the stores and get a 2 gallon can of oil and to go up No 1 pit headgear and oil the pulley wheel bearings.

The concrete headgear must have been at least 100 foot high with foot high steps with a handrail on only one side, making it hard work going up with a 2 gallon can of oil. When I got to the top the hand rail ran off at an angle making it very frightening. I eventually got up there, oiled the bearings, lay down flat on my belly and tried to climb backwards dragging the can with one hand, after several attempts I threw the can off the head gear and used both hands to get down. The oil can was smashed and I had to return it to the stores and tell the store man it had slipped out of my hands, he told me he was going to see the engineer and have apprentices stopped from going up headgear with oil cans as every time they came back damaged. So it was not only me that had trouble with the steps.

While on the top I noticed a shelter and was told that a member of the home guard used to be up there looking out for German ships or aircraft approaching the coast during the second world war, this reminded me of a miner who had his locker in the pit head baths next to mine Markie Sweeting was his name. His body was badly scarred and I can remember asking one of the old timers if Markie had been in an accident down the pit, I was told the tale about how Markie and 2 others were in the Home Guard in position on the cliff tops when a German bomber dropped a land mine on a parachute, thinking it was a parachutist they tried to shoot him. They succeeded in hitting the land mine and it blew up over them, I was told that one was killed outright, another never worked again and Markie suffered injuries that he eventually got over.

I was friendly with Alan Harvey and during the Hippy period when I had a beard down to my waist and shoulder length hair we decided that we would pack our apprenticeships in and go to San Francisco.

That Sunday I was working the usual Sunday shift of 5.30am to 11.30 am, showered and travelled home with my father who was also at work that day. My father was a very fair man, he never drank, swore or smoked, his only vice was his model trains, any way this Sunday Mam was finishing cooking our Sunday lunch while me and Dad sat at opposite ends of the dining room table reading our Sunday papers. I said to him that I was putting my notice in on the Monday and was going to San Francisco with Alan Harvey. Dad lowered his paper looked me in the eyes and said “Peter do you not think its time you grew up” he raised his paper up before lowering it again and saying to me “its also about time you got a f—ing haircut” Mam dropped the pan on the stove and rushed into dining room saying Jonny you swore, you never swear in the house. Needless to say I did not go to San Francisco, Dad never ever swore in house again and I never got my hair cut.

Across the road from the colliery entrance (the two stone pillers are still there) you had the canteen car park next to the canteen with the pit baths stretching to the junction of the High Road and the Coast Road. The entrance to the baths was behind the economic bus stop, you stepped in to the clean side lockers. These lockers you stripped naked and put your clothes in, taking only your bait, towel and soap you walked past the showers to the dirty side and changed into your pit clothes. At the end of your shift you stripped your dirty clothes off, showered and put your clean clothes on ready for home.

No one ever locked their lockers even on a Friday when you were on back shift and drew your wages before going on shift. Can remember one year when one lad claimed that he had his holiday pay stolen from his locker, three weeks wages in total about £80, every one was shocked and a whip round was organised and it was rumoured he ended up with over £100.

During the holidays he was full of drink and was heard bragging how he had conned every one by claiming his wages had been stolen, swift justice was administered to him and he was told never to go back to the pit because he would not be allowed to return to the surface. He was never seen again and was reported to have left Shields.

Coming out of the dirty side you past a revolving brush that you used to put dubbin on your pit boots to keep them supple, just past this on the right fitters and electricians picked up the paperwork for their statuary inspections. After this you exited the baths past the disused covered ramp across the road that was last used when the rattler carried passengers. You crossed the main road up the stairs to the lamp cabin to pick up your lamp, then down to the clocking in office, Bobby Dack was the time keeper. After clocking in you picked up your 2 brass numbered tokens, still remember my number 1787, stepping out you walked 30 or so yards to the pit heap and the cage, you handed one of your tokens to the banksman and kept the other one in your pocket. I can remember many heated arguments with miners and officials about work loads, Whitburn was known as the blood and thunder colliery and it was not unusual for the men to go home in disputes. I was told the tale of one disagreement that a decision was made to throw a half brick in the air, if it came down the men would go home, unfortunately the man tasked with throwing the brick up got carried away and the brick never hit the ground it landed on the time office roof.

When I was an apprentice we went straight from the time office to the fitting shop, as part of our training we had to spend a month working in the other workshops, first off we had a month in the blacksmiths shop. Names I can remember from the black smiths, Jimmy Robertson from Sunderland his family had a fish and chip shop near the Wheatsheaf, David Allen who was known as Monty because on leaving school he worked in Montague Burton cloths shop. Billy Hood brother of the fitting shop welder Bobby, Alby Cauwood was another one, can remember him always singing the first lines of “How are things in Glocknamara” Gordon Harper was the blacksmiths striker.

Outside the main door of the fitting shop. To the right the blacksmiths mental store, blacksmith shop and joiner shop.

Front row Myself (Peter Webber) Alan Harvey, Billy Durrant.

The rear of the fitting shop the electrical shop to the right.

Front row Geordie Anderson, Alan Harvey, Bill Durrant

For some reason we never got to work in the joiners shop, it could have been because John “NODDY” Charlton lost his fingers in the circular saw. Someone had asked him to fill a bag of sawdust from the joiners shop. John went in the joiners shop and stood back while a joiner finished off using the saw, as soon as the joiner switched the saw off and turned away and put his hand in to collect the saw dust not realising that blade had not fully stopped. Poor John was running round like a headless chicken and it took several blacksmiths and fitters to catch him and take him to the medical centre.

Another shop we spent a month in was the tub shop repairing damaged tubs, names I remember from there was Joe Gouch, A very fair but firm man, we did what Joe told us to, Old Harry Parkes and Billy Waggot are two more I remember from there. We also spent a month in the electric shop, the foremen were Albert Bayfield and Wilfy Wilson, several of the electrical apprentices were. John Scott from Marsden who ended up as electrical superintendent at Press on the Tyne. Keith Waller from Whitburn who went to Canada when pit closed and died out there at a young age.

Fred Jackson who moved to Nottingham when pit closed, called in to see him in the 70s when I was working in the area, he eventually moved back up here and last time I saw him he was repairing fruit machines in pubs.

Another close friend who I met up with during my travels as a service engineer was Jeff Farrow, when Whitburn closed Jeff moved to Rolls Royce at Derby, he married the barmaid from his local and ended up as managing director of a factory producing large plastic bottles.

Tom Jones is another that I have rekindled my friendship with. Tom ended up going to sea after the pit closed, he lives out near No Name after having to give the sea up when he was diagnosed as diabetic. Only found out recently that Billy Mac the engineer was his brother in law. Billy Elwood was another, his father was a pump man down number 2 pit .

The two labourers in the electric shop was Seppy Preston who only had one lung and little Billy Roberts. All the electrical apprentices received their underground training from my father who was the bellman down No 1 pit who looked after all the telephones and signals, He died suddenly on Christmas Day 1999 aged 75 and it was heartening to see all the ex-employees from Whitburn who attended his funeral.

Lastly but not least a name that still upsets me. Alan Jackson, we went every where together places like the old mechanics lodge and the dances above the co-op in old Marsden village, the Fuse Box and the Purple Onion. We drifted apart when he started courting Kathleen his future wife, I went to their wedding but lost touch when I moved to Jarrow in 1972. We had a mutual friend Fred Newman who passed my regards to Allen and he did the same to me. When the pit closed Allen went to sea, one day in rough weather in the Bay of Biscay the bow light went out, suspecting that it was the bulb he sent the ships boy to change it, to protect himself he told him to crawl forward over the top of the scrap cargo that were carrying. After several minutes of not hearing from the boy, the mate went to investigate, when he did not appear Alan chose to go himself to investigate leaving the only other member of the crew the captain on the steering wheel. All 3 perished due to the scrap metal cargo that they were unaware was mainly cast iron, this heats up when rubbed together and takes the oxygen out of the air. I went to Alan’s funeral and when the coffin was brought in the church I turned round and for a minute I thought Alan was following the coffin, I realised it was Alan’s son Rodney who at 24 was the spitting double of Alan who was that age when I last saw him.

Depending what shift I was on I would often walk to work from my home in Quarry Lane to the pit, a walk of 20 minutes duration. On leaving estate would go up the hill on the High Road passing Marsden Hall where the NCB had offices, during the war US troops who manned a searchlight unit on Cleadon Hills were based there.100 yards past the entrance to the Hall on the opposite side of the road you passed the Horse Stables, with a path running from there down to the reservoirs.

These stored fresh water for the steam boilers at the pit, there were two reservoirs the oldest one was about the size of a football pitch with a maximum depth of about 3 feet, it was on here that we built and sailed rafts when we were kids. Next to it was the new reservoir, this was about a quarter the size of the old one but was about six foot deep with steep sloping sides, when we were older would often swim in it. It was here that a tragic accident happened about 1963, a group of 6 and 7 years of age from my estate were playing there when one of them Philip Summerson fell in and drowned, his friends panicked and ran for his Dad instead of seeking help from the Golf Clubhouse or the stables, I can still picture old Sammy carrying the body of his youngest son home.

Past the stables the golf course was on the right with a bit further on the 19th hole, the golf club. Past the club house you came on a short row of cottages on a road heading down towards the old pit village at Marsden, I was told that at one time this was a toll road. A lad from the pit Jacky Hunter leased the field next to the cottage he lived in, in this field was our playground, the site of a large naval gun. You entered it by going down a rusting steel staircase about 50 feet deep. On the opposite side of the stairs were rows of rooms with iron bars on the windows, someone had thrown red paint over them, and we used to think it was blood. At the bottom you made your way through passages till you came to a massive circular hole where the large gun turret sat. When I started at the pit was told that when it was first built they fired a shell out to sea over the top of the old village the resulting vacum which broke the windows of the Co-op and sucked the tiles off the roof. It was never fired again and the gun was removed before the second world war.

Continuing past the dungeons you passed the pig field before heading down the hill from the High Road to the pit baths, passing on the left allotments and 2 rows of pit houses, the front row facing the pit was usually occupied by colliery officials, can remember the undermanager of No 2 pit living there, as well as Charlie Hartiss the training officer, other names I remember from there was Paddy Turner, Alan and Fletcher Sharp, Jimmy Robson, Jimmy Angus. Across the road at the pit entrance what is now the Whitburn Lodge Pub was the No 1 pit manager Jack Eccles house, next to it was the mortuary. As apprentices we were often sent to fill the coal house, weed the garden or do any jobs that Mrs Eccles wanted doing. There was never any shortage of volunteers as she was a lovely lady who always gave us pop and biscuits. My youngest son broke his leg 26 years ago when he was 6 years old, I arranged to borrow a wheel chair from the red cross and the person I saw was Mrs Eccles over a cup of coffee we talked about the good old days.

If the weather was bad I had the option of catching the pit bus that ran to Shields after every shift, can remember getting on one winter morning after finishing night shift, sat next to an old timer from No 2 pit who I only knew by his nickname Dodger. In those days the only television during the day was a couple of hour’s horse racing in the afternoons which I had no interest in. Dodger because of his deafness shouted when he talked to you, this morning he insisted that he had a red hot tip for me in a race at Haydock, 2 Door Leg End was the name he shouted at me. I read my morning paper before going to bed but could not see the horse. That night I met Dodger in the baths and he shouted “DID YOU BACK IT” I told him I could not find it in the paper, he produced his paper and pointed at a horse called Tudor Legend, he shouted “THERE IT IS, 2 DOOR LEG END”. No wonder I could not find it.

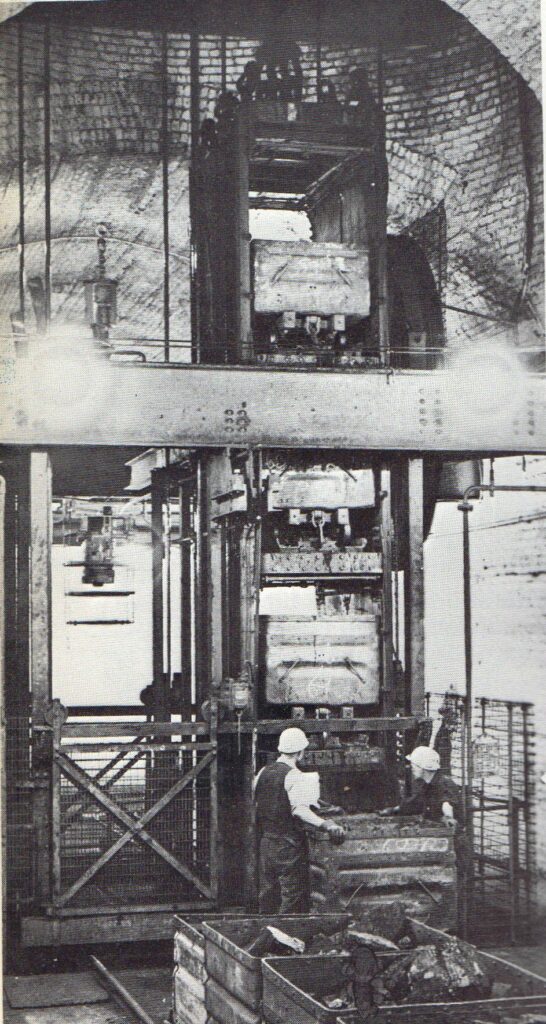

There were 2 shafts at Whitburn Colliery, No 1 shaft was the deepest at 1100 feet deep, it was the shaft with the concrete framed winding tower. This was open to the atmosphere and was known as the downcast shaft as all the fresh air for the mine went down that shaft. The shaft was 13 foot diameter with 2 cages running in it, these cages kept in position with the aid of wooden guides that ran the length of the shaft, shoes on the outside of the cages gripped the edges of the guides. The cage had 4 decks, the top one held about 12 men and was about 6 foot high, the other 3 decks were only tub height of about 4 foot and each held 8 men who sat on their honkers. Coal was brought to the surface with 2 tubs per deck total of 8 tubs every wind. On entering the cage you handed one of your numbered tokens to the banksman, that way an accurate check was kept of how many men were underground, when you finished your shift you handed your other token to the banksman so a record could be updated of numbers underground. These tokens were sent to the time office by means of tubes the size of toilet roll holders sent down a pipe by means of compressed air. When the onsetter let you out of the cage at shaft bottom you usually got in one of the two mansets to go inbye. Number 1 pit was the more modern of the two pits, it was operated on the horizon mining method where all the roadways were used by battery operated locos that brought coal outbye in sets of 40 tubs, returning in-bye with sets of empty tubs. Two districts operated in No 1 pit during my time there, West Hutton and the Yard seam.

Stepping out the cage you were facing Whitburn village, on the right you had the loco battery charging station, this had 2 rail lines with 5 battery racks on each side of a line, there was 5 locos with full batteries and 10 on charge at any time.

Stepping out on the other side of the cage you had the roadway that used to lead to the old High Hutton seam, in my days it was the route that the empty tubs were coupled up into 40 tub sets. Over this line you had the water sump for all water that was pumped outbye from both pits. 2 eight stage mackley centrifugal pumps pumped water out of the pit up a 12 inch pipe that ran up to the surface. These were ran in rotation every night with weekly services, in the event of one breaking down everything was dropped to get it operating again, can remember once when the 6 inch diameter drive shaft sheared, I worked 32 hours non stop with Raymond Robinson until pump was repaired, I thought it was great because it was organised for meals to be sent from the canteen for us.

Looking towards Whitburn you had the manriding trams, 2 sets of 4 carriages in each set, one set for the West Hutton District the other for the yard seam, loco was only allowed to travel at 10mph with manset but was allowed to do 15 mph with coal sets, that might not seem fast, but when you had girders passing within 6 inchs from the side of your face it was fast enough.

The shaft landing stretched to a point that I would guess was under Derek Wilsons garage, the full sets of coal were pulled to within 100 yards of pit bottom, loco was then uncoupled and was supposed to go through the points onto the inbye line, change the points run down past the set, change the points then reverse behind the set and push it down to creepers that slowly dragged tubs towards shaft. The young lads who were loco drivers found this was too much bother getting in and out to change points so they would get onto in bye line and fit a chain from loco to first tub and pull them onto creepers that way.

This was against all the rules and woe betide any one who was caught, one of my mates Bob Johnson from Shields was caught by the undermanager, he was told to report to the office after his shift with his license for driving the loco. Bob went to Jack Eccles office after his shift and had the riot act read to him, he was told to produce his license as it was going to be ripped up, Bob said you cannot do that, Jack Eccles threw a wobbler shouting and screaming at Bob telling him he had to do what he was told, Harry Thomas the deputy engineer ran into the office thinking some one was getting murdered, Jack Eccles asked Bob again for his license, Bob again refused saying if you rip it up I will not be able to drive. Harry told me later that both him and Jack Eccles could not understand what Bob was on about so Harry said show it to me, so Bob produced his car driving license. Harry said this is not a loco license, Bob said oh it is and opened it up and showed them both, classes of vehicle allowed to drive included “light locomotives”. Harry said it took them both a while to compose themselves before Bob was told to bugger off and go to see the training officer to arrange having a test to drive underground locos.

Going in-bye at the end of the landing you came to a junction to the East that took you 2 or 3 miles to the East Yard seam, continuing from the landing for another half mile heading for Whitburn roadway turned right heading towards Cleadon Hills after another mile or so roadway swung right again heading underneath Redwell School. You eventually came to a stage loader that filled the tubs from a large hydraulic powered bunker into which conveyors had tipped coal into to ensure that belts did not have to stop when there was no tubs waiting to load. At the end of this bunker, you turned right and followed the conveyor belt into West Hutton 4 and 2 faces. At the end of this belt was an old timer who operated belt and looked out for any spillages, I often sat and chatted with him while having my bait, one day my father passed and seeing me he pulled me to one side and told me not to talk to him again as he was a communist.

The West Hutton seam was 4 foot 6 inches high, No2 coal was cut by the plough method, No4 where I did my face training with Jacky Nicker was operated with a treppaner cutting the coal, this was a state of the art machine at the time and produced very large lumps of coal.

Riding the conveyor belt was against the rules but every one did it, better riding 2 miles than walking, you just had to be careful about picking your spot for getting on or off. Was coming outbye one day riding the belt, when I approached the point where the belt from No2 face fed onto the one I was riding on. I dropped down from a knealing position to flat on my stomach to pass under the front of the other belt, unfortunately my lamp cable from my cap light to battery was sticking up and as I went under the conveyor it got caught and pulled it out of the battery. I was pitched into total blackness where I could see nothing. I knelt up on my knees and stuck my hand out till I felt a steel wire that hung from the roof to support conveyor frame, as soon as I grasped the wire I clung on and jumped as far as I could from the conveyor. I then had to sit in total darkness until someone came out-bye to lead me to shaft bottom.

As I have said riding the belt was a serious offence if you were caught, never the less most men rode the belt out bye, one day when an apprentice I was riding the belt following the fitter I was training with, Bob Patterson. 20 yards from the end Jack Eccles, who had been stood with his light out suddenly switched it on and pulled the signal wire to stop the belt. He proceeded to give Bob a right telling off, when he finished with Bob he told me that he would be telling my father about me riding the belt. I had a little smile to myself as I knew my father always rode the belt.

Can remember one funny incident about riding the belt, a neighbour of mine Billy Baron who was a stone man was working in the roadway taking up a bottom rip. Over time with the pressure on the arch girders the floor would buckle upwards, to remedy this, the excess was dug up and thrown on the belt, this was called ripping. Underground from the days when you had ponies the place was over run with mice, can remember sitting in a sub- station in the warm eating my bait, when I finished I nodded off due to the warm air from the electric panels heating the sub- station up, before going to sleep I turned my light out so no one passing would see me as it was a sackable offence to be caught asleep underground. After a couple of minutes I could feel something scratching my arm and legs, I turned my light on and saw several mice eating my grease covered boilersuit, that was the quickest wake up alarm call I ever had.

To keep your bait safe from mice you would hang it from the girders by a length of thin shot wire, in them days bread came in grease proof wrapping so it was usual to have your bait wrapped up in this. No one bothered with bait boxes as in them days they were too bulky and heavy it was enough having to carry your water bottle clipped to your waste.

Anyway Billy was working alongside the belt with his bait hanging from the roof above the belt when the shift started coming out-bye kneeling on the belt, as they passed Billy they would greet him and at the same time stick a nutt on his bait tied up on the shot wire, when Billy went to eat his sandwiches he found them all flattened .

Next day he thought he would put a stop to this abuse of his bait, he ate his bait before the shift change, shat in the grease proof paper and carefully tied it up on shot wire. The first man riding past shouted “all right Barron” before nutting the presumed bait on the shot wire, Barron said the next word he heard was “you rotten b—ard”as he made contact. No one touched Barons bait after that.

Another incident involving Billy Baron who was as hard as nails occurred at the shaft bottom, an electrician Geordie Brewis who was known as a gentle giant who never argued with anyone was sitting in the manset waiting to go in-bye.

As was usual it was normal to empty your water bottle before riding to bank at the end of your shift. This day Baron decided he would sprinkle every one sitting on the manset with water, Geordie said “no Baron I cannot be bothered”, Billy still sprinkled Geordie who sat up and punched Baron straight on the point of his chin. Billy fell to the floor unconscious and had to be taking to the medical centre on a stretcher. Billy had to make a statement to the safety officer, in his statement he said he had slipped on the wet steel sheets that every one emptied their water bottles on. The next day to everyone’s amusement notices appeared banning the emptying of water bottles at the shaft bottom.

The other district down No 1 pit was the East Yard seam, just passed the end of the shaft landing the roadway split in two, straight on was the route to the West Hutton, the other route involved a left turn to take you under the sea, after a couple of miles you came to the Yard seam landing. Sets of tubs were filled from 100 foot high bunker, this was filled by a conveyor belt that came up a one in three drift from the seam. This was the only belt in the pit that man riding was allowed on, it had proper landing stages with platforms that allowed you to stand upright to get on and off. At the bottom of the drift you had 2 faces each 300 yards long and 2 foot 10 inches high, coal was cut with Anderson Boyes shearers.

One day the shearer on one of the faces cut into some old water filled workings, the force of the water turned the shearer on its side and it was a miracle no one drowned, the whole of the yard seam was evacuated. The water eventually stopped at a level half way up the one in three drift. Pipes and pumps were sourced from all of the pits in the Durham area, squads of fitters from the area workshops flying squad were called in to assist our own fitters to lay 2 lines of 3 inch pipes from the water level in the drift to out-bye. One squad started from top of drift and the other squad from the bottom meeting in the middle of the drift, all went well till they met up and found they had fitted the pipes on opposite sides. Can remember Old Freddy Jackson the pipe fitter saying no problem soon put that right, he had a twenty foot length of pipe wedged behind an arch girder while 2 or 3 men slowly pulled on it until it was bent to an angle of 45 degrees, he repeated this with 3 other pipes and soon had the lines connected. The pumps worked 24 hours a day for weeks till water was all pumped out. The face was closed due to the old workings suspected from being there since the 1800’s when collieries used to steal coal from their neighbours reserves, in this case they reckoned Hylton Pit was responsible. I worked with the team who salvaged the machinery off the face and had a look in the old workings; they had holed into an old roadway junction with a perfect brick built archway about 8 foot high.

The other shaft to the North of No 1 was the upcast shaft for No 2 pit. All the dirty air from the pit circulated to the surface up this shaft, to gain access to the shaft on the surface you had to go through an air lock. This shaft was 700 feet deep with the same diameter 13 feet as No 1, 50 feet below the surface there was the fan drift with a fan of at least 20 foot diameter that sucked the dirty air out of the pit allowing the fresh air to enter pit down No 1 pit, the return workings were a lot hotter than the fresh air roadways. This shaft had a 6 foot plug at its bottom, below this plug the shaft was sunk to the 1100 foot level for future development, unfortunately this was still unused when pit closed.

From the shaft bottom you had the disused landing for the East Yard 17 seam, this was worked out when I first went down pit, however it still had a pump in-bye. In its working days coal was hauled to the shaft bottom by means of a main and tail haulage rope powered by a 375 horse power electric hauler, the roadway out to the old face took about one and a quarter hours to travel, it was only tub height of about 5 foot high making it uncomfortable travel. My father told me it was common practise to get in an empty tub and ride in-bye, strictly illegal but better than walking bent double for over 3 miles. He told me he was going in-bye one day when a set was getting ready to depart so he jumped in and braced himself with his back against rear of tub and feet pushing against front of tub, halfway in the set came off the way, the haulage operator seeing the rope jerk and the amps rise knew the set was off the line so he switched hauler off and sent for the wagon way men to put it back on the tracks. Fortunately tub my father was in remained upright, but as there was only 3 inches clearance from tub to roof he had to remain in it for over 3 hours till they managed to get set into the in-bye landing.

When I started work on the pit heap there was a lad called Rolf who only had one arm, it was marvellous to watch him roll a cigarette in the bait cabin with one hand, it was obvious that he had a lot of pain from his injury as he was always taking pain killers. I was told he had been placed on a conveyor transfer point even though he was under age. Down pit you had to be 18 before you could operate machinery, this day Rolf was using a shovel to clear the belt while it was in motion, the shovel got caught dragging Rolfs arm into belt drive, they said he braced himself against the frame and rather than allow his whole body to be dragged in he allowed his arm and shoulder to be torn from his body. It was said the Deputy who had placed Rolf in that job saved his life by tying his torn arteries and stopping the blood loss, the deputy and five other men put Rolf in a stretcher that they placed in a empty timber tram and ran all the way to the shaft bottom and to the surface for a waiting ambulance to rush him to the Ingham Infirmary, it was said all the men required treatment for exhaustion in the medical centre.

It was in East Yard 17 pump that I first saw an adult man cry, a 4 inch diameter pipe had split 3 or 4 pipe lengths out-bye side of pump. Old Freddy Jackson the pipe fitter had measured up and had a replacement pipe made in the fitting shop, I was tasked with carrying the pipe in for Freddy and helping him fit it. When we arrived at the damaged length Freddy undid one flange and I did the other, these pipes were called Albion flanged as at one end they had a loose turn-able flange while the other end had a cast fixed flange. We offered the pipe up and discovered it was about half an inch short, not to worry said Fred, loosen about 6 pipe flanges, fit pipe and then pull pipes together using ring spanner. This we did but pipe was still not nipped up enough, Freddy told me to put the ring spanner on one of the bolts and use my weight by standing on the spanner to tighten the joint, after getting about half a turn on the bolt Freddy said do the opposite side bolt. I stood on the ring key and pushed, the spanner went loose and all you could hear was “ping” “ping” echoing out-bye . About 8 lengths of pipe had their cast flanges sheared off, an upset Freddy had to phone Billy Mac the engineer to say we needed at least eight lengths of pipe making up.

When an apprentice was in his last 6 months he was allowed to do jobs on his own without supervision, these jobs would be to pump repairs or haulage engines, the idea was that the pumper or haulage operator had seen repairs done on countless occasions on their equipment and could assist the apprentice if he needed help. I never had any bother with this and learned a lot from the old pumpers who if they had the spanners and tools were capable of doing the job themselves.

Before I was sent on my first unsupervised job I was warned to take notice of any thing the operator said to me. I was told the tale of an apprentice electrician who was sent to the East Yard 375 horse power hauler to rectify a fault, when he arrived at the haulage engine he diagnosed the fault to be in the contact breakers. These were in an oil filled bath with a big ships like wheel on the end for lowering the oil bath, he lowered the bath and went to put his fingers in, the operator said are you sure its down far enough as they usually lower than that. The apprentice lost his rag and said who are you to tell me what to do, the operator repeated his warning and got more abuse so he sat back down and watched the apprentice put a finger from each hand to grip the contactor. The contactor was still live, as the operator had said not clear of the oil bath, that made the electrical circuit, the electric shock burnt off the fore finger of each hand and flung him against a girder causing burns on his chest and his ear where he was earthed against the girder. Attempts were made to sack the 60 plus year old operator he was told he should have stopped the 20 year old apprentice by using force, When the miners got to hear about it they vowed to a man that they would strike. He kept his job and the electrician was forever known as Paddy two fingers.

Another district down No 2 pit was the six quarter seam, it was a three foot high seam with the coal cut by a BJD Shearer, the shearer was hydraulic operated and pulled it self the length of the face along a heavy duty spring loaded chain. The shearer was mounted on top of the Armoured face conveyor or Panzer as it was commonly known as, the panzer consisted of H section pans about 5 foot long and about 2 foot wide, the coal was moved by bars fixed to chains every 15 links that ran in guides on the top and bottom of the pans that were bolted together to make a conveyor of about 250 yards length. The coal was carried on the panzer to the main gate stage loader from where it was loaded onto main conveyor belt to go out-bye. As the shearer moved along the face the panzer was jacked over towards the coal face by about 3 foot , the cutting width of the shearer disc. It was the face fitters job to ensure the panzer chain was correctly tensioned, if it was too slack it could come out of the guides when panzer was jacked over, to refit chain was a major operation taking about a day to complete. Each fitter had to ensure there was a full set of different length chains of 3,5,7,9,11, and 13 link lengths. If panzer had excessive slack when it went round the drive sprocket the chain had to be shortened by taking out a 15 link length and substituting it with a set of shortened links. The correct method of doing this was to stop the shearer and allow any cut coal to be ran off the belt, then two hydraulic pullers were dragged from the main gate, attached to each side of the panzer chain and pumped till all slack was taking up and new shortened links fitted, this was hard work and could mean face stopped from cutting coal for about an hour. An easy illegal way we used to shorting chain was to have a prop wedged between panzer bar and roof, reverse panzer and the drive would pull all the slack chain over the drive sprocket, then you had to whip the old length out and fit new length before panzer motor cut out with the strain. The secret of doing this was to have some one you trusted doing one side while you did the other and you had to ensure that you only held the chain with the tips of your fingers so if the prop slipped in theory you could pull your hand clear, can still remember one fitter who had fingers missing from this type of operation. The Deputy knew what you were doing but turned a blind eye because he knew using this method we only had the panzer stopped for 5 minutes max.

As part of my surface training as stated previously we apprentices had to spend a month in various different departments, I had just returned to pit after doing a month in the shearer overhaul shop at the area workshop when Billy Mac the engineer called me to his office. He asked me if I had been taught how to change the hydraulic drive on a BJD Shearer while at the Area Workshops, I told him yes, he told me to go to the six quarter and change a pump that had been sent from Area workshops. When I arrived at the face, the face fitter old Jack Thompson had the covers off the drive unit, most of the shift was sitting watching while I fitted new drive. When I finished and the shearer worked, the deputy shook my hand and thanked me, it made my day, do not know how I walked out-bye that day as my head was that swollen.

It was not long after this that Jack suffered a sad loss, his son was killed in a car that came off the road on the bend near the rifle range farm, he was a passenger in a car driven by a lad from Marsden who was serving his time with him at Harton Pit. The lad was called Jimmy Hodgson and was convicted of causing death by dangerous driving. I met him a couple of years after the accident and he was still full of remorse, He told me he had applied to work in the pits in Canada but he was not allowed to emigrate because of his conviction.

Sets of coal tubs were hauled by a main and tail hauler, this was where the main rope was fastened to front of full set and was used to pull set out-bye, to the rear of the set was fastened a tail rope that the set pulled along behind it. On arrival in the out-bye landing ropes were disconnected from full set and fixed to empty set that was hauled in-bye by tail rope with main rope on rear of set.

From the landing a creeper moved the tubs till they came to the bottom of a steep drift that ran at right angles up to No 2 shaft landing, the tubs were transported up and down drift by an endless haulage. Two full tubs at a time were attached to the ascending rope while two empty tubs descended on downward side of drift, These tubs were attached to the rope by clips that gripped the rope , 2 lads did this dangerous job as it was not unusual for tubs to come away from rope, as a safety measure there was extra large refuge holes for them to jump into. A lifelong friend of mine was not so lucky one day the tubs ran amain and as he dived in the refuge hole one of his feet was crushed, he ended up with nearly every bone in his foot crushed. When he recovered he never went back to the pit, Bill Cauwood is his name, he is now retired and lives at Cleadon, his late father William (who I only knew of by his nickname of Tilly), Bill’s Auntie Annie Cauwood who worked in the pit canteen lived near us at Marsden. Bill lived in the street called the Homes on Redwell Bank when I first made friends with him 62 years ago.

At the bottom of the drift where Bill got hurt, the roadway extended about another 20 to 30 feet to accommodate the endless haulage return pulley and a mono pump that was operated by a ball valve, when the level rose to a certain point float activated on switch to start pump, when level lowered pump switched off, the deputy monitored this and he was responsible for reporting any faults. You used to hate calls to this pump because you were always looking over your shoulder for tubs breaking away, fortunately none ever did when I was working there.

The six quarter seam was very wet in places, the foul water that dripped on you often caused boils on your body. One cure to heal them was to take an empty milk bottle into the shower, glass bottles were not supposed to be taken into showers, but in them days you never got antibiotics so if you did not want a bread poultices put on the boil you used the milk bottle. The open end of the bottle was placed over the boil and very hot water was directed onto bottle, this caused a vacuum that drew all the badness and the core from the boil. Miners working in the wet got a wet payment of about one shilling and sixpence, Tradesmen got paid a six hour shift meaning you could go to surface after 6 hours and be paid as if you had worked a full shift of seven and a half hours, we always worked our full shift and claimed the wet money of about seventeen shillings and ten pence.

I would often get called to a broken down pump in the old district in the six quarter, the pump operator was old Billy Ellwood whose son Billy was an electrician, the first time I was sent in-bye to the pump I was travelling with my tool bag over one shoulder holding my cap lamp in my hand. This was the usual practise as it allowed you to watch where your feet were treading, as I got near to the pump old Billy who was stood in a refuge hole with his light turned off suddenly jumped on my back, to say I got a fright was an under statement, it took ages for my heart to stop racing. Next time I got a call to Billy’s pump as I got near I shouted out “Billy its Peter and if you jump on me I will belt you” Billy put his light on and stepped out of a refuge hole 20 yards in front of me complaining “that you young ones have no sense of humour”.

The other working face down No 2 pit was the North Yard 33 face, again this was a three foot high face about two hundred and eighty yard length with an AB Shearer cutting the coal. The mother gate that contained the conveyor that carried the coal out to the in-bye landing where the sets were loaded for hauling to the shaft bottom landing with a main and tail haulage system. The main gate stretched a long way taking about 30 minutes to walk to in-bye landing. Total distance from the shaft was 3 to 4 miles, down the pit you were allowed 20 minutes per mile travel time.

One day I was working on the face covering for a fitter who was off sick, I was sat in the Mothergate when I got a call to attend a fault in the tail gate. To walk out-bye then back in-bye would have taken about an hour so I decided that the easiest way was to crawl along the face to the tail gate, about fifty yards down the face I met a neighbour from Marsden old Alfie Burges. Budgie asked where I was going, when I said the tail gate he said no turn round and walk around. I said do not be stupid and move out the way so I can crawl past, when I said this Budgie blew his top and said I would have to crawl over him and he would call in the Bakers shop next to the Lake where my mother worked to tell her I had disobeyed him. Budgie explained to me they had just sheared through a fault and the roof of the seam was in a dangerous state and they had sent for the manager to come and inspect it. I turned crawled off the face and started to walk round, when I got half way down the tail gate there was a woosh of air and dust that came racing down the gate, the roof had caved in on the face where the fault was, the face was closed for nearly two weeks while the fall was cleared and the face made safe.

Budgie told every one in the Lake and the Marsden Inn how he had saved my life, it used to cost me a pint every time I met him in a pub.

Down No 2 Pit the fore shift overman who was the senior official underground was Jimmy Angus who lived in the houses across the road from the pit. We used to have a saying to insult a person “you are as thick as Jimmy Angus”, my first dealings with Jimmy was when I was an apprentice in the fitting shop when I answered the phone to him. In those days the phone had no numbers to dial just a handle that you turned to ring all the phones on the system, the head pieces were fastened together and sat on your shoulder covering each ear. This day the phone rang twice, the signal for the fitting shop I answered it and a voice said JAY here I want some panzer links for the North Yard 33 face, what length I asked, Jimmy replied some this length and some this length and hung the phone up. Obviously he was indicating the size with his hands, when I told Billy Prince one of the foreman fitters he laughed and he said just cut a full set of links and have them sent to him. Another time JAY as he insisted everyone addressed him as, sent a note to the fitting shop asking for 6 sheets of corrugated iron, he had used about six attempts to write corrugated iron, crossing each attempt out and finally asking for 6 sheets of wriggly tin.

The best example of JAY was one Saturday in the North Yard was when I and another fitter were fitting a new electric motor to the shearer. The electrician arranged for the power to be turned off at the shaft bottom so we could change the 5 ton motor using a Sylvestor to drag the motors about. After about 4 hours hard graft we had the motors changed and the electrician wired the new one up. I stood by the controls and asked JAY to phone shaft bottom to turn power on, this he did shouting “power on” I turned the controls but nothing was happening so I shouted to JAY “its not working have the power turned off”. JAY removed the phone headset from his shoulders and told me not to be so impatient, he said how long did it take you to walk here from the shaft bottom, “about one hour twenty minutes” I replied JAY said that’s your trouble you are not giving the electricity time to get here.

When I left school you had the choice of usually 3 jobs, the pit, shipyards or the armed forces. A few of my school friends got jobs at Whitburn, they started on the pit heap, then progressed to working underground as datal hands then when they were in their twenties and there was a vacancy they moved onto the face at the highest wages in pit. This was the National Power loaders agreement, this was £22.50 a week when Whitburn closed. Old timers told me in the fifties they could earn double or triple this wage on piece work.

An important job done by datal hands was timber leading a job that involved getting materials like props and arch girders and other materials that were needed on the coal face. One of mine and Bill Cauwood’s friend, Bob Robertson had a painful accident in the North Yard, he had collected a tram of props that had been brought into the in-bye landing with the empty set of tubs. In the old days a pony would have hitched up to the tram and pulled it down the mothergate to the face, but it was decided that it was cruel to have ponies working underground so the datal hands used to have to push the trams in and out the gate. The tram had a chain on the front that attached to a hook on the rear of the next tub in front of it; the mother gate ran with a slight incline running in-bye. This day Bob perched on the back of the tram and pushed himself along using his feet to push tram along by pushing off each sleeper, tram was moving nicely with just the occasional push to keep momentum going, Bob decided to eat his bait, his mother had wrapped his bait in the previous day’s newspaper. Bob decided to read the paper while eating his bait knowing it would be at least 40 minutes till he arrived at face, he was not concentrating where he was placing his feet to push against the sleeper, suddenly the heel of Bobs boot got caught behind a sleeper. This caused Bob to stop while the momentum kept tram moving, the coupling hook went straight up Bobs backside before ripping itself free leaving Bob bleeding and in agony. He ended up with numerous stitches and for months he had to walk about with a sanitary towel covering the wound till it mended, he got the mickey taking out of him a lot after that.

Another timber leader down No 2 pit was Cocka Simpson, we used to always use him on weekends if we needed any equipment moving to a job. One Sunday we were changing a drive drum on one of the main and tail haulers, Cocka had manoeuvred the new drum into engine house while I and another fitter removed the damaged one. When we removed damaged drum Cocka went to take it out to the tram, we had our coats hung up there as it was red hot in engine house, I asked Cocka if he would look at my watch and see what time it was. A couple of minutes later he came back with a sketch of my pocket watch showing where the hands were, the fitter I was working with said why did you show him up by asking him to check your watch, you must know he cannot read or write. To say I was speechless was an understatement, as far as I was concerned I had no idea as Cocka was known as best timber leader at Whitburn. The fitter I was working with Dennis Thompson told me the tale of how Cocka was on the sick and took a doctor’s note to the medical centre so it could be entered in the book there, the attendant looked at the note saw the doctor had just drawn a line through the box that asked reason for being off work.He said to Cocka what was wrong with you, Cocka said the doctor has wrote on the note, the attendant said all I can see in the box is a stroke, Cocka said that’s what must have been wrong with me then.

In the summer months absenteeism from work was regular, the favourite reply to why did you only work four shifts the previous week, was because I could not manage on three. Can remember one red hot summers day lying on the grass listening to the cricket on my transistor radio, I was due at work on 4pm shift but England were playing Australia in the ashes and Colin Milburn was hitting them all over the ground, that was one shift I missed.

From being a boy when my father took me to Roker Park to see Len Shackelton I had been a supporter of Sunderland, Used to follow them home and away, would go to the away matches with the economic bus ,used to join it at the Grey Horse after it was loaded with crates of beer. In them days it was unusual to see any violence at football grounds, in fact used to mix with the home fans so we could have some good natured banter, on the way to the games we always had plenty of drink and to relieve yourself you had to stand on the door step and slightly open the sliding door so you could pee outside. After the match we used to find a pub and stay there till closing time arriving back at the Grey Horse in the early hours of Sunday morning. Can remember one game at Grimsby, we ended up drinking in Cleethorpes and got friendly with a lad from Sunderland, he ended up on the bus going back to Whitburn, passing through Sunderland someone woke him up to ask where he wanted dropping off. He looked puzzled and said I do not live in Sunderland, I have a family in Cleethorpes.

I was at Roker Park that fateful day in the FA cup replay in 1964 when the gates at the Roker end gave way to the sheer weight of the supporters waiting to enter being pushed against them. I was carried through the gates by the crowd behind, it was bedlam people had falling down and the crowd was piling on top of them, fortunately I managed to shoot off to the side and take refuge behind a support, as I looked at the crowd I saw a fitter from the fitting shop Billy Arkley lying on the edge I dragged him to behind the pillar and stayed with him until he was taken to hospital with a broken leg. The next home game was against Middlesborough with the usual 60 to 65000 crowd; I put up with it for 30 minutes and could not handle the panic attacks. That was the last time I ever watched a professional football game.

In 1961 Alf Robens a former trade union leader and former Labour member of Parliament for Blyth was appointed by a Tory government as chairman of the NCB . Lord Robens as he was then along with a new labour government led by Harold Wilson decimated the pits of Britain, when he became chairman there was 695 pits, 10 years later when he left there was only 292 left. The miners were very badly let down by the Labour Party that they helped to create, pits were not allowed to spend money developing new coal seams. The Labour government even allowed a nuclear instead of coal fired power station to be built in Hartlepool, a real slap in the face to the Durham miners.

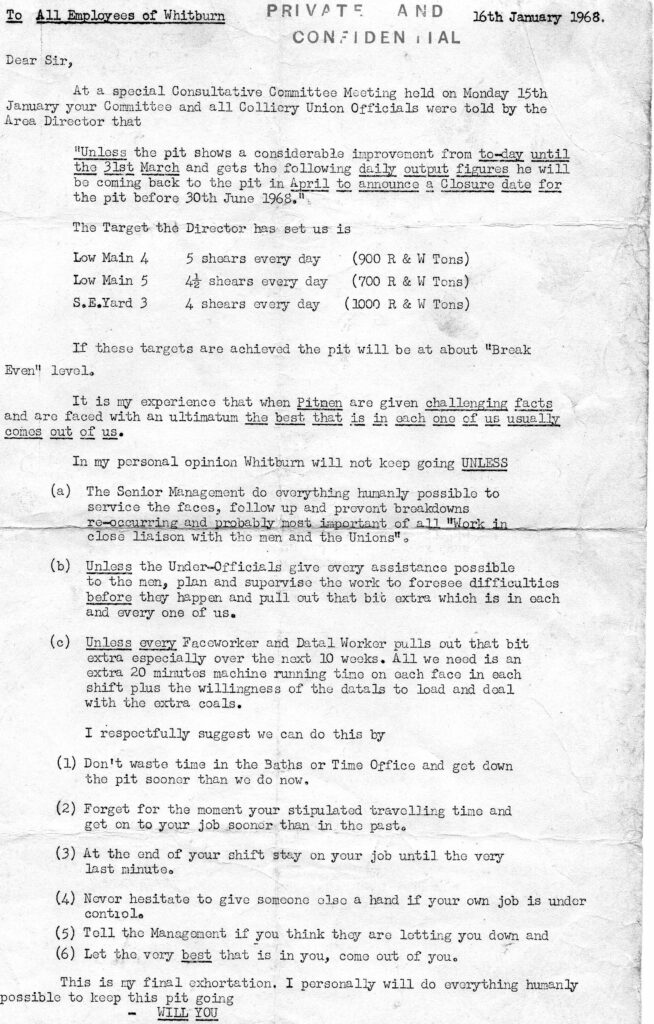

In 1968 it was Whitburn’s turn, all development work had been stopped and only 3 operational faces remained, all yard seams. We all received letters saying if output did not rise Pit would close, can remember going to a Union meeting after this letter was sent and can remember the real hatred directed at the Labour government. I still feel bitter to this day and have never voted Labour since.

In spite of the miners doing the best they could and even beating the target figures by May the NCB announced that pit would close in June 1968 as they had planned since they had first issued the letters. Older miners over 58 years of age were offered redundancy payments, everyone younger was offered jobs at Westoe, Wearmouth or the chance to move to Nottingham Coalfield, redundancy payments were not an option.

The NCB made arrangements for interested men who were considering moving to Nottingham to spend a weekend there looking at Pits there and housing. I was still living at home with my parents and 19 year old brother when I went for job interviews with my father, I was offered a job at Bevercotes which was the most modern pit in the country, Dad was offered a bellmans job at Ollerton. We were taken to Tuxford and shown new council houses that were being built and my parents were even asked to pick plot they wanted. We discussed this on the bus journey back home and agreed if my younger brother who was serving his time with GPO telephones agreed we would move down as a family. My brother refused to consider moving as he was courting a girl down the street, we decided we would not split the family up so on the Monday we returned the letter we had refusing the job offers. The NCB then offered us both jobs at Wearmouth, my father accepted but I refused and was prepared to look in yards or even go to sea rather than to Wearmouth. With days to go I was called into office and asked if I wanted a job at Westoe as Raymond Robinson had turned down a fitters job there. He went to work in an ex pit surveyors Jeff Liddles car repair garage at Ada Street South Shields eventually moving to a new site next to the church in Whitburn.

I accepted the job at Westoe and worked there for 20 months, hating every minute of it, Whitburn was a family pit with sons following their fathers to working there, you knew everyone and you could always rely on getting help whenever you needed it. In the 20 months I was at Westoe I never even got to know all of my fellow fitters, lots of the men there came from the pit villages in the West of Durham, locals would have a chin wag in the baths but these men were always in a rush as they had to catch their buses back home.

I put up with this till February 1970 and accepted a position as a service engineer with Avery Hardoll servicing and repairing their liquid measuring equipment, based at home I was one of a team of six engineers that covered the British isles from Channel Islands, all of Ireland the Hebrides, Shetland and Orkney. Like thousands of ex-pitmen who loved their work I did not believe better jobs existed, but many who left the industry after their pit closed ended up with jobs breathing fresh air. Just before returning to work after your annual fortnight off you would stop bringing up coal dust, once you returned to work it was back to normal, it never ceased to amaze me the number of retired miners with chest problems that led to premature deaths. My father went to Wearmouth and lasted a year before he got the opportunity of a chauffeurs job with the NCB at the Area Workshops, he died Christmas Day 1999 aged 75.

Myself I worked with Avery Hardoll for 30 years, when working in Nottingham would often stay at Newcastle Arms in Tuxford and see many of the lads who moved there after pit closure. Was once in a pub in Retford where I stayed on a regular basis, one day a women’s dart team from Ollerton was playing there, I was sat near the dart board talking to one of the locals I knew when one of the women said you sound just like my son-in-law who moved down here from South Shields in 1968. I asked his name, John Anderson she said, I said I knew him well he was a fitter at Whitburn, I could not believe how small a World it is. In this pub,

The Sun Inn I was very friendly with a few regulars who worked in the local pits, one day after the big strike of 84 had been going for about 10 months one of them who was on strike asked my opinion of his plan to return to work. I told him the tale of old Billy Macdermid the engineers father who had gone back to work during the 1926 strike and was still called a scab 40 years later.

In April 2000 I was offered a redundancy package that I could not refuse plus I was starting to get sick of the travel and being away from home. I was retired for 6 weeks when I they rang me up asking if I would consider going back to work on a self employed basis to teach new engineers, I laughed and said no thanks. I continued to get requests from my old manager to reconsider, then one day I received a call from the MD who I never got on with, he was appointed to the job straight from University and had no experience of man management and was part of the new school that thought that a worker should have nothing to smile about at work.

When I described how we loved going to work on a Monday at Whitburn he thought I was taking the mick. He said to me he had made a mistake in letting me go and to name my price for going back, when I finished my rate was just under £10 per hour. I told him I would return for £25 per hour thinking he would leave me alone. When can you start he said, I worked for them for another 3 years before setting up my own company doing all the work I did while at Avery Hardoll .

I employed my brother to help me and then took on my oldest son to learn the business, 3 years ago I caught swine flu and ended up in intensive care with kidney failure after 3 weeks I was released on Christmas eve 2010 only able to walk with the aid of a zimmer frame. My son was thrown in at the deep end and came through with flying colours expanding the business so we now employ an apprentice and another engineer while I continue to work at 67 doing all the paperwork and job arranging.

I have no doubt if Whitburn had stayed open I would not have left the NCB, but I often wonder how long I would have lived after retirement, can remember many miners who died with in 12 months of retirement, like Alfie “Budgie” Burgess and two of my other friends who worked together all their life together at Whitburn and transferred to Wearmouth. They both retired on a Friday and had plans to share an allotment together, on the Saturday Billy Baron collapsed and died in his garden 3 doors away from my home at Quarry Lane, on the Monday his friend Ken Chapman died as well, some say it was the shock of Billy’s death that killed him.

Peter Webber (Jarrow 2013)

Peter Webber 1947 – 2015 RIP

All copyrights acknowledged were known.

B Cauwood 2013

updated 2020

Copyright © 2013 Marsden Banner Group.

All rights reserved. Permission granted to reproduce text for educational use only (please cite source).